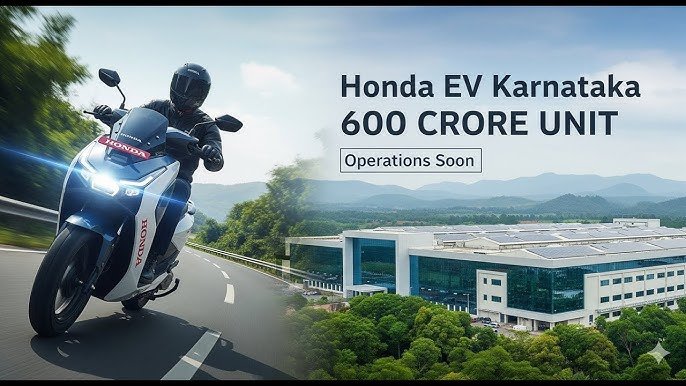

KOLAR, KARNATAKA—Honda Motorcycle and Scooter India (HMSI) is set to invest ₹600 crore in establishing its first dedicated electric two-wheeler manufacturing facility in Narasapura, Karnataka, accelerating the Japanese giant’s push into India’s burgeoning EV sector. The announcement, made by Karnataka Industries Minister M.B. Patil in early September 2025, came after a high-level meeting with Honda executives in Japan. This strategic move not only strengthens Honda’s commitment to sustainable mobility but also positions Karnataka as a key hub for advanced EV manufacturing, creating jobs and fostering local supply chains.

The new plant, adjacent to HMSI’s existing Narasapura facility—which already produces over 2.4 million two-wheelers annually and stands as the company’s largest in India—will focus on producing electric scooters for both domestic sales and exports. This aligns with a memorandum of understanding signed earlier in 2025 at the Global Investors Meet, signaling Honda’s long-term bet on India’s electric mobility ecosystem.

Background: Honda’s EV Journey in India

Honda’s entry into India’s electric two-wheeler space began in early 2025 with the launch of two models: the Activa e and the QC1 electric scooters. The Activa e, in particular, features an innovative battery-swapping system, with Honda planning to roll out swappable battery stations in major cities like Delhi, Bengaluru, and Mumbai to address range anxiety and charging infrastructure gaps. These initial steps laid the groundwork for scaled production, as Honda aims to become India’s top electric two-wheeler manufacturer by 2028.

The ₹600 crore investment reflects Honda’s global vision of carbon neutrality by 2050, adapted to India’s unique market dynamics. With EV two-wheeler sales surging—projected to reach 40% market penetration by 2030 under government incentives like FAME-III—Honda is responding to rising demand for affordable, eco-friendly commuting options. The Narasapura project builds on HMSI’s existing infrastructure, where the parent plant already meets 98% of its energy needs through renewables, underscoring a commitment to green manufacturing.

The Narasapura Plant: Key Details and Timeline

Located in the Narasapura Industrial Area of Kolar district, the new facility will be commissioned by 2028, with construction expected to commence soon after regulatory approvals. Spanning an area adjacent to the current 1.2 million-unit capacity plant, it will leverage shared logistics and skilled labor from the existing setup. Honda’s total investment in Karnataka, including suppliers, now exceeds ₹5,400 crore, with the new EV unit set to generate hundreds of direct jobs and thousands indirectly through ancillary industries.

Key highlights include:

- Production Focus: Electric scooters like the Activa e and QC1, with potential for future models featuring advanced battery tech and swappable systems.

- Capacity: Initial output targeting 100,000-200,000 units annually, scalable based on market demand.

- Technology: Integration of Honda’s proprietary e:HEV hybrid tech adapted for pure EVs, emphasizing lightweight frames, efficient motors, and smart connectivity.

- Sustainability: Solar-powered operations and zero-waste goals, aligning with Karnataka’s green industrial policies.

The minister’s delegation, including Principal Secretary Selvakumar and Commissioner Gunjan Krishna, highlighted Karnataka’s semiconductor ecosystem and skilled workforce during the Japan meetings. Discussions also touched on partnerships with firms like Mitsubishi Electric and Tokyo Electron for component sourcing, further embedding the plant in a high-tech supply chain.

| Aspect | Details |

|---|---|

| Investment | ₹600 crore |

| Location | Narasapura Industrial Area, Kolar District, Karnataka |

| Timeline | Commissioning by 2028; construction to start soon |

| Annual Capacity (Initial) | 100,000-200,000 units (scalable) |

| Products | Electric scooters (e.g., Activa e, QC1) for domestic and export markets |

| Job Creation | Hundreds direct; thousands indirect via suppliers |

| Energy Source | 98% renewable (building on existing plant) |

Economic and Strategic Impact

This investment is a win for Karnataka, which has aggressively courted Japanese firms amid global supply chain shifts. The state, already home to Honda’s largest two-wheeler plant, now eyes EV leadership, with the Narasapura facility boosting local GDP and skill development. Patil emphasized, “This project will create significant employment opportunities in Karnataka’s automobile sector,” during the announcement.

For Honda, the plant addresses localization challenges, aiming for 90% local sourcing to qualify for subsidies and reduce costs. It comes at a time when competitors like Ola Electric, Ather Energy, and TVS are ramping up EV production, with Ola’s 1 million-unit capacity in Tamil Nadu setting a high bar. Honda’s focus on premium, reliable EVs—backed by its 25-year legacy in India (cumulative production: 70 million units)—could carve a niche in the mid-to-premium segment, where the Activa e is priced around ₹1-1.5 lakh.

Exports to ASEAN and Europe will further elevate India’s role in global EV supply chains, with Narasapura’s proximity to Bengaluru’s tech hub enabling R&D collaborations. Social media on X reflects excitement, with users hailing it as a “game-changer for sustainable commuting” and speculating on battery-swapping networks expanding nationwide.

Challenges and Opportunities Ahead

While promising, the venture faces hurdles: India’s patchy charging infrastructure (only 10,000 public stations as of September 2025) and subsidy uncertainties under the upcoming FAME-III scheme could slow adoption. Intense competition and raw material price volatility for lithium-ion batteries add pressure. However, Honda’s global expertise in battery management and its partnership with Indian suppliers position it well to navigate these.

Opportunities abound in urban markets, where two-wheelers dominate (over 80% of vehicles sold), and government targets for 30% EV penetration by 2030 provide tailwinds. The plant could also spur ancillary growth in battery recycling and component manufacturing, fostering a circular economy.

Conclusion: Electrifying India’s Two-Wheeler Future

Honda’s ₹600 crore EV plant in Narasapura is more than an investment—it’s a bold step toward electrifying India’s roads and cementing Karnataka’s manufacturing prowess. By 2028, this facility could propel HMSI to the forefront of the EV race, blending Japanese precision with Indian innovation. As Minister Patil noted, it’s a partnership that “strengthens India’s electric mobility push.” For commuters and exporters alike, the Activa e’s successors from Narasapura promise a greener, faster ride ahead.